Brand/Medium

Product & Application Resources

Filters

Color

Non-color

Application

Information

Resource Type

What do the icons mean?

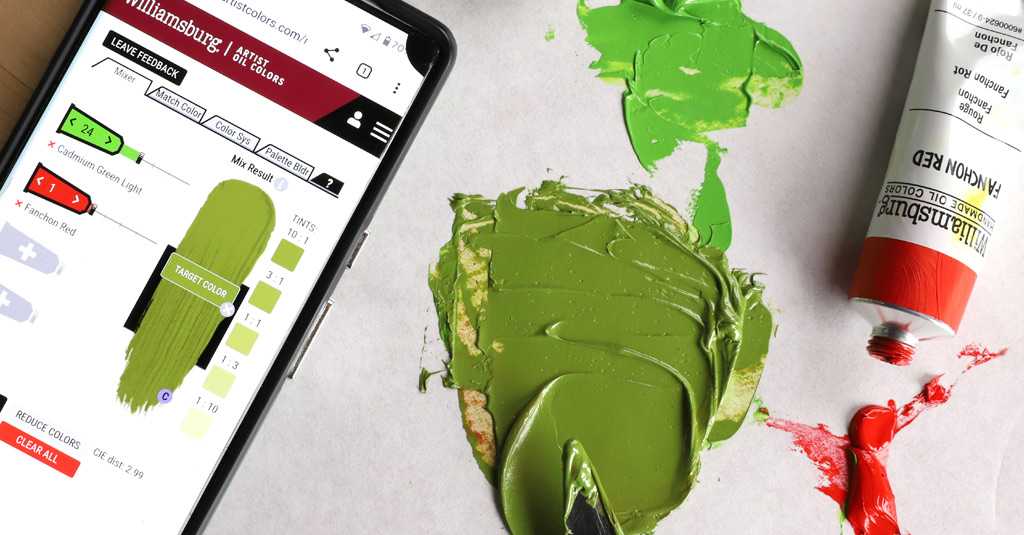

Try our NEW acrylic paint mixer

Our newly enhanced mixer allows acrylic and oil artists to create personal palettes so you can mix with the paints in your studio, plus instant comple...

The Story Behind the New PanPastel Colors

As soon as GOLDEN acquired PanPastel in November 2022, we began hearing a repeated call from artists: “new colors please!” In February 2025, we delive...

Basic PanPastel Techniques

A visual guide to some basic PanPastel techniques

Fabric Painting with Acrylics and GAC 900

Fabric painting on wearable garments is not a difficult process. Find mixing recipes, application techniques, heat-setting methods, and laundering ins...

Using PanPastel Mediums

A brief visual tutorial on using PanPastel Mediums

PanPastel Surface Guide

A guide to using PanPastels on a number of different surfaces.

Color Mixing with PanPastel

A quick walkthrough of mixing colors with PanPastels

PanPastel Drawing Techniques

A visual overview of drawing techniques using PanPastels

Using Sofft Tools

A quick overview of using Sofft Tools with PanPastels.

PanPastel Painting Techniques

A visual overview of basic painting techniques using PanPastels.

PanPastel Lesson Plans for Art Educators

A collection of lesson plans to help art educators teach fundamentals with PanPastels.

PanPastel Mixed Media

A visual overview of some of the mixed media techniques available with PanPastel

1 / 37