INTRODUCTION TO VARNISHING

The application of varnish is a is a complex issue that does not lend itself to easy solutions because no single varnish or technique is right for every situation. Desired appearance, type and thickness of application of underlying media, texture and absorbency of the surface, and interior versus exterior conditions of exposure are common factors influencing varnish selection and application techniques. Understanding varnishes capbilities and limitations will greatly enhance the likelihood of success.

APPLICATION DESCRIPTION

Functions of a Varnish

Varnish can assist art work in several ways. It can be used to change surface gloss, making a surface more matte or gloss, or provide painting with a more unified overall finish. Varnish can also increase color saturation and offer protection for the underlying paint surface facilitating easier cleaning. It is also often used to consolidate art work, in a similar manner to a fixative for charcoal or pastel. Some varnishes offer additional protection in the form of Ultra Violet Light Stabilizer, which dissipates UV radiation before damage can occur. These varnishes are especially useful for materials that are fugitive in nature, such as dyes, but cannot render them completely lightfast. Thicker films (coats/layers) of varnish with UVLS provide greater protection.

Requirements of a Varnish

Varnishes should be removable to allow for cleaning without damaging the underlying surface. The use of a removable varnish provides a valuable tool to anyone trying to restore or clean the painting by allowing it to be solubilized and removed, taking with it any surface contamination. The varnish must be flexible enough to move with the painting surface, yet be hard enough to resist retention of grime and dust by providing a nontacky surface. Depending on the substrate and environmental conditions, it must be formulated with the correct porosity to either allow moisture to pass through or provide a moisture barrier. It should have good chemical and water resistance. Over time it should resist discoloration caused by factors like humidity, heat and visible and ultra violet (UV) light sources. Finally, the varnish must possess excellent clarity, without discoloration or fogging.

Aesthetics of a Varnish

In all cases, varnishes serve an aesthetic function, whether desired or not, due to a difference in the refractive index between the varnish and what is underneath it. A "perfect varnish", that does not alter the appearance of the painting, is often requested, but has never been fully achieved. Therefore, varnish is most successfully used when it compliments the painting. Practice and experience will provide an understanding of how varnish affects the look of a painting. Varnishes are offered in a range of finishes, from gloss to matte, to allow the artist control of the sheen. Different finishes of the same brand can usually be intermixed within each product type, or used sequentially, to achieve any desired level of gloss.

Types of Varnish

A recent conference at the Canadian Conservation Institute was dedicated to the discussion of the current state of the art and science of varnishing for the paintings conservator. The symposium covered traditional natural varnishes such as Dammar, Copal, Mastic and newer synthetic varnishes with names like Laropal K-80, PVAA/AYAB, PVA/AWAB, Mowilith 20PVA, Ketone N, Arkon P90, Regalrez and Polybutylmethacrylate. These materials were reviewed by the material scientists and conservators for their suitability as a varnish for modern and earlier works of art. Although most of the discussion of these varnishes and their viability as coating for works of art are beyond the scope of this paper, some discussion of the earlier varnishes and some of the new systems helps put the topic of varnishing into better perspective.

The most important traditional varnish is dammar. It is the only traditional coating system that is still recommended as suitable for a work of art. Other resins, such as copal or mastic, although unfortunately still in use, suffer from cracking, extensive yellowing, and become increasingly difficult to remove from a painting over time. Although dammar does turn yellow to brown within about fifty years of normal exposure conditions, it is still removable from an oil painting surface without greatly affecting the paint layers below.

The search for a better alternative has moved to the newer synthetic varnish systems. Quite a deal of discussion has recently centered around low molecular weight varnishes, such as the new varnish by Gamblin, GamVar, and high molecular weight (HMW) varnishes such as our MSA varnish. A low molecular weight varnish will tend to have greater gloss, higher refractive index and will provide greater saturation into the surface, due to the smaller molecular size, than high molecular weight varnishes. On the other hand, HMW varnishes tend to offer a better protective surface, have greater elasticity and more resistance to blooming.

Although some new work by René de la Rie, Head of Scientific Research of the National Gallery of Art, has suggested various alternatives, we continue to prefer the polybutylacrylate systems, Golden MSA Varnish, which have so far proven the most durable and lightfast, and maintain their removability. Our other varnish, Golden Polymer Varnish, is unique in that it offers a water-borne varnish which meets the criteria of remaining removable and having good visual properties, while freeing the user from hazardous solvent exposure. In terms of film toughness and permeability, this varnish provides an intermediate level of performance compared to the MSA Varnish. Rigid supports allow the use of much harder varnishes. This is especially important when applications involve functional use of the artwork, as in furniture or floor designs. Often the varnish of choice in these applications is a polyurethane because they provide some of the most non-porous and toughest films available. They often fail the rule of a removable coating, but this may have to be accepted, depending on the application. Polyurethanes which have been available the longest, the aromatic type, are prone to yellowing. However, recent innovations have provided polyurethanes that do not yellow. These are of the aliphatic type. They can be purchased as water-based or solvent-based products, in both single and two part systems.

Varnishing Acrylic Paintings

Some practitioners of conservation and art instructors recommend that paintings done with acrylic emulsion paints not be varnished, because of the potential difficulty in removing the varnish without affecting the paint film. Our research and experience indicate that with the right varnish and technique, varnishing of such paintings is advantageous and risks are minimized. Acrylic paint, being a thermoplastic polymer, tends to soften under conditions of high temperature and/or high humidity. This makes it more vulnerable to retention of dust and dirt particles. A varnish that is harder than the paint will reduce this, while providing a sacrificial layer for cleaning. However, it is critical that the varnish maintain good flexibility if the support for the painting is also flexible, as with canvas or paper.

In order to protect the paint film if varnish removal is required for restoration purposes, we recommend that an intermediate layer of an isolating medium be applied. An isolating layer is a transparent film that physically separates the underlying layer of paint or other medium from the varnish to be applied. When a solvent is used to dissolve the varnish, the isolating layer will prevent it from reaching the paint layers, where damage, mostly in the form of color pickup (solubility), could occur. The isolating layer is also of critical importance when applying a matte varnish over an absorbent surface (such as a stained surface) to prevent a cloudy or "frosted" appearance from occurring. This frosted appearance results from the varnish and solvent being absorbed into the support, while the matting agent remains exposed on the surface, where it appears as a white solid. Golden Soft Gel (Gloss) thinned with water is a suitable isolation coat. It provides adequate leveling and foam release.

Varnish Application

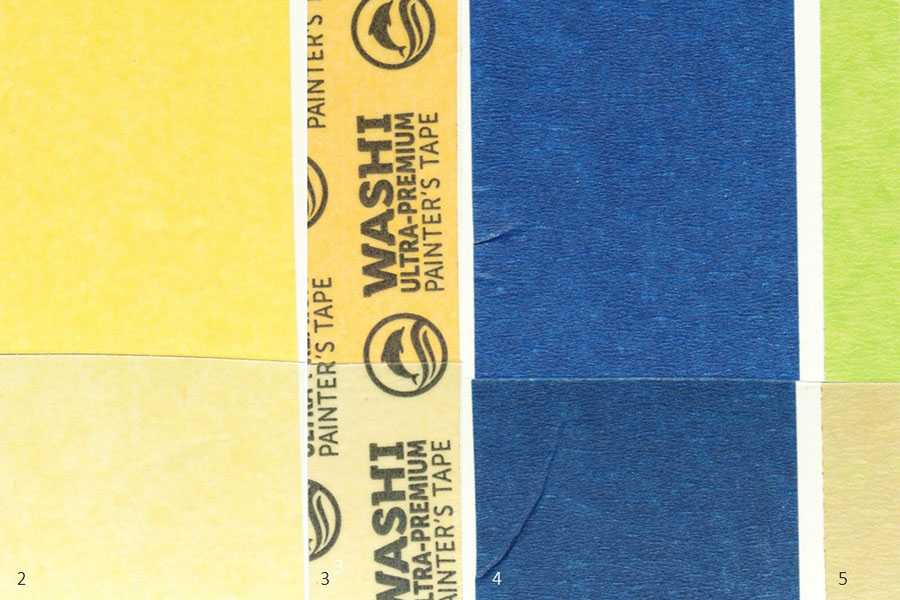

The most critical part of achieving success with varnishes is the application. Unfortunately, varnishing is considered as an afterthought, or is rushed through to finish and ship the artwork. For successful application, the user must be thoroughly versed in proper techniques, as well as the inherent properties of the varnish. It is very important to spend some time experimenting with the varnishes on test pieces, in order to become familiar with the products.

James Bernstein, Conservator of Fine Paintings, offers the following method for brush-applying varnish: The technique I use for brush varnishing proceeds as follows. A varnish solution of appropriate viscosity is prepared and then transferred to a low profile, wide-mouth, weighty (tip-proof) vessel. The vessel is filled with only a shallow volume of varnish, so that the solution will wet only the lower tip of the brush (1/4 to 1/3 the total length of the bristles).

Prior to proceeding, a varnish application strategy must be determined. For this, the boundaries to be covered with each brush dip of solution need to be envisioned. At times, the varnish is applied in square or rectangular sections, following a grid of overlapping regions. Still other times, varnish is applied in free-form sections, following compositional features or outlines.

Before dipping and brushing, estimate the amount of coverage possible for even distribution with each dip. When proceeding, always place the loaded brush in the middle of the section to be covered. The solution is then spread out evenly saturating the entire section. The next dip is placed in the center of the next area to be covered, not directly adjacent to previously varnished area. After filling the present section, the still wet application is often finished with quickly brushed, low angle strokes, lightly overlapping the wet varnish across the transition edge where it meets the previously applied, partially set varnish field. The painting is varnished thusly, going from section to section until complete.

For spraying varnish, which we feel is generally the best method of application, Mr. Bernstein recommends: Always pre-test spray settings and solutions to observe the handling and forming of the varnish before attempting to spray any art. Once adjustments are made, spraying is begun at a far corner of the painting, continuing across the surface in an uninterrupted linear pass. Constant distance is maintained (e. g. 10-14 inches) and spraying proceeds past the outer edge of the painting, where a turn in direction takes place for the next, slightly-overlapping, parallel pass of varnish. Spraying continues in this manner until the entire surface is covered. For subsequent varnish applications, the spray orientation may be switched by 90 degrees (e. g. , horizontal passes for the first coat, vertical for the second, and so on) to ensure uniform distribution. 1,2

Care and Storage

Let varnish cure several days before packing or transporting art. During transportation and storage, avoid contact of the surface with packing materials, including glassine, bubble wrap or any other plastic. NEVER STACK PAINTINGS, whether varnished or not. Please refer to the following Just Paint article for more information about the handling, storage and transportation of acrylic paintings:

Safe Handling and Transportation of Acrylic Paintings

The above advice is the product of extensive experience, training and knowledge of materials. Professional conservators are often expert in the field of varnish application and have the equipment to do the job right. Having a conservator perform the varnishing of paintings is an alternative worth considering, especially for works of special importance.

1 Varnishes, Authenticity and Permanence Colloquium, September 19-20, 1994

2 A Review of Varnish Application Fundamentals, 1992 AIC Paintings Specialty Group Postprints, American Institute for Conservation of Historical and Artistic Works, 1400 16th Street N. W. , Suite 340, Washington, DC 20036

Disclaimer

The above information is based on research and testing done by Golden Artist Colors, Inc., and is provided as a basis for understanding the potential uses of the products mentioned. Due to the numerous variables in methods, materials and conditions of producing art, Golden Artist Colors, Inc. cannot be sure the product will be right for you. Therefore, we urge product users to test each application to ensure all individual project requirements are met. While we believe the above information is accurate, WE MAKE NO EXPRESS OR IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, and we shall in no event be liable for any damages (indirect, consequential, or otherwise) that may occur as a result of a product application.