CRACKLE PASTE

GOLDEN Crackle Paste is a thick, opaque cracking material, designed to develop deep fissure-like cracks as it cures. The size and extent of the crackle pattern is dependent on many factors, including the thickness of application, and the environmental conditions (temperature, relative humidity and air flow) during drying.

This product utilizes defects in the film formation process, and controlled failure is problematic. This results in the cracking performance being variable and to some extent unpredictable. GOLDEN has provided the most current and comprehensive knowledge of what may be expected while using this product, but artist-conducted testing will ultimately assure more reproducible and sound applications.

PRODUCT DESCRIPTION

Crackle Paste is a water-based product formulated with styrene-acrylic copolymer emulsions, and may have a tendency to yellow.

This product has white, low-density solids that replace traditional fillers. Its unique ratio of specific solids and binders allows for a "controlled failure" to occur and the result is its tendency to crack. It has a consistency similar to cake icing, easily manipulated by a palette knife. Peaks will maintain their height and appearance. It is a harder film than the GOLDEN Light Molding Paste, yet still retains an absorbent surface.

Films dry to an opaque, matte finish to which subsequent layers of acrylic paint and mediums can be applied. Crackle Paste can be easily tinted with GOLDEN Heavy Body, Matte, High Load and Fluid Acrylic Paints.

It is imperative to test all aspects when working with GOLDEN Crackle Paste. This is a highly variable product, and it should NOT be assumed that it will perform exactly the same each time the product is used. Review this information carefully and conduct testing before using this product on artwork or decorative finishes.

Drying times greatly depend upon film thickness. Very thin films will dry to the touch in several hours but may not develop much cracking. Increasing film thickness will increase the tendency to crack and also the size of the cracks and platelets. Cracks can take several days to fully develop.

Do not force dry Crackle Paste, nor try to slow the drying by adding Retarder or other additives, as both conditions may interfere with the products ability to crack. Product should be allowed to cure between 65oF and 75oF, and under 75% Relative Humidity.

Crackle Paste cleans up with soap and water. Do not let products dry on tools. Keep tools wet while in use. Soak tools in soapy water to remove dried films.

APPLICATION INFORMATION

Substrates

Shows how canvas will warp if this product is applied.

While it"s possible to apply Crackle Paste onto a wide variety of surfaces, the extreme shrinking can warp flexible products like paper or canvas. Therefore, applications onto rigid supports such as wooden panels, sheetrock (decorative/faux finish applications) or hardboard are recommended.

If an application on canvas is desired, prestretch the canvas before applying the Crackle Paste. This minimizes the warping of the canvas during drying. If paper is the desired substrate, it may be glued to a rigid support with an acrylic medium [such as Soft Gel (Gloss)] and allowed to dry to before applying the Crackle Paste.

By securing the substrate or using a rigid support, the Crackle Paste has the greatest opportunity to develop the best possible pattern.

Surface Preparation

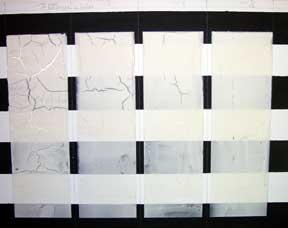

The thicker the application, the deeper the cracks

Priming the substrate is critical as it increases the adhesion of the Crackle Paste to the surface, which in turn reduces the amount of "cupping” that can develop as the film dries. Cupping generally leads to early delamination, and makes sealing the surface more difficult and uneven.

One or two coats of GOLDEN Gesso are an ideal surface preparation. Other GOLDEN products, such as Gel Mediums and paints may also be used directly underneath Crackle Paste, but testing should be done to assure proper adhesion. The GOLDEN High Load Acrylics are an excellent choice for use as a colored ground.

House paints may also be used for decorative applications onto prepared interior walls. These paints should not be used on flexible supports because of their tendency to crack and delaminate if flexed.

Application Methods

Like other thick and pasty gel mediums, Crackle Paste will retain tool marks. The most practical way to apply Crackle Paste is with palette knives or trowels. In tests, we have found that while the cracking pattern is essentially random, ridges and peaks will influence the pattern to an extent. Smooth, consistent applications will produce the most regular pattern. The thickness of the application is directly related to the size and quality of the cracking fissures. Skim coats may have such tiny cracks that it may not even appear to have cracked at all. A good starting thickness is around 1/8 inch films. Films nearing 1" thick may develop few, and incomplete cracks (cracks more on surface, but not entirely through the film).

Mixing with Acrylic Paints

A unique aspect of the product is the ability to tint Crackle Paste with acrylic paints. GOLDEN Heavy Body and Fluid Acrylics are the most commonly used paints and additions up to 10% by volume (20% by weight) have been blended successfully without greatly altering the cracking ability. Over additions of paint may result in a failure of this product to crack.

Gel Mediums may also be blended with the Crackle Paste. Additions up to 10% by volume (20% by weight) are suggested. One advantage of adding a gel medium to the Crackle Paste is that it increases the overall film strength, reducing fragility and increasing adhesion. Over-adding a gel medium will reduce or eliminate the cracking ability.

It is important to understand how the properties of each gel can impact the viscosity, rheology, sheen and texture. For example, adding Regular Gel (Matte) should not alter the appearance of the Crackle Paste, but will increase the overall film strength and begin reducing the absorbency. Adding Polymer Medium will thin and add leveling, and potentially increase gloss. Create small mixtures and test on the same kind of prepared substrate intended for the actual product application.

For thinner applications, it is best to simply use the tool to apply it and do NOT thin with water. Adding water to the Crackle Paste may result in poor performance and delamination. While adding a thin medium to the Crackle Paste to reduce viscosity is acceptable, remember not to go beyond the 10% by volume (20% by weight). Understanding the nature of the medium utilized will impact the finished properties of cracking, gloss and adhesion. GOLDEN Fluid Matte Medium works best to reduce the viscosity of the Crackle Paste while minimizing other changes.

Reducing Yellowing Aspect

Testing in a QUV Weatherometer TM has shown exposure to UV light causes the Crackle Paste to begin yellowing. After a simulated 50 years of gallery-lit conditions (2 – 400 hour cycles in a QUV Weatherometer TM), the degree of yellowing is noticeable. After a simulated 100 years of gallery-lit conditions (4 – 400 hour cycles in a QUV Weatherometer TM), the yellowing is moderate, but very noticeable.

Adding Titanium White pigmented paint (tests with 5-10% additions of GOLDEN Heavy Body Titanium White showed noticeably less color shift) can help to offset the yellowing from becoming significant. Additionally, the use of a varnish containing UltraViolet Light Stabilizers (such as GOLDEN Polymer Varnish or MSA Varnish) will greatly reduce the amount of harmful UV light reaching the Crackle Paste.

Drying Times

As with any acrylic paint film,temperature, relative humidity, airflow, absorbency of the substrate, and film thicknesswill impact the actual drying time of Crackle Paste.

Generally, most cracking occurs in 24 hours or less, but thicker applications (1/2" or more) may actually take up to three days or more to fully develop all of the possible fissures.

Do not force dry Crackle Paste, nor try to slow the drying by adding Retarder or other additives, as both conditions may interfere with the product"s ability to crack. Product should be allowed to cure between 65oF and 75oF, and under 75% RH.

Fresco-Like Applications

When Crackle Paste is still wet, acrylic paints can be directly applied before the cracking begins. This results in the image developing cracks in the paint films applied over it as well as the Crackle Paste itself. By misting the surface lightly with water, while painting quickly, one can create the look of deteriorating frescoes. Used in conjunction with Light Molding Paste, which does not crack but looks and feels very similar, this application allows for interesting effects.

Post-Cracking Paint Applications

Once the Crackle Paste has cured, other products may be applied over it. Note however, that excessive paint layers can cover or fill the cracks. Applying the paints more thinly, or application of thinned paints, washes, glazes, and spray-applied products are better suited for such a textured, absorbent surface.

Topcoats

The cured film of Crackle Paste will be highly porous and absorbent. Once the application is complete, sealing the surface with a topcoat further increases the longevity of the product. Additionally, by sealing the surface, the cracks are more readily highlighted, minimizing the staining of the product surface.

For brush application, 2:1 Soft Gel (Gloss):water mixture can be used successfully if applied carefully. Avoid rapid or excessive brushing, as this can cause foam bubbles that may not come out of the topcoat layer. Consider spray applications of products for this purpose, such as a 2:1 mixture of GOLDEN GAC 500:Airbrush Transparent Extender (refer to Information Sheets, Beginning Airbrush Tips I ,Beginning Airbrush Tips II, Isolation Coat, or contact GOLDEN Materials and Applications Support for further information about spraying GOLDEN products).

As the Crackle Paste is an absorbent film, before applying a Matte varnish, the film must be isolated first (see above), using the appropriate gloss product. This will avoid the potential for a frostedappearance, which may result when applying a matte topcoat over absorbent materials.

GOLDEN MSA or Polymer Varnishes w/ UVLS can be applied, once all work is complete. Follow appropriate directions for such.

COMMON PROBLEMS

Platelets Cupping /Not Adhering to Surface

- Surface improperly prepared

- Surface is too flexible

Product isn"t Cracking/Incomplete Cracking

- Product not cured under proper temperature or humidity conditions

- Product applied too thin, micro cracks develop instead of deep fissures

- Too much acrylic paint or medium was added to the mixture

- Substrate was too flexible or not tacked down, and curled rather than developing cracking pattern

- Product applied too thickly (over 1" thick)

Product is too Fragile

- Surface improperly prepared. Add Gel Medium to increase film strength

- Water added to product. Possibly can be fixed by the use of a topcoat.

Disclaimer

The above information is based on research and testing done by Golden Artist Colors, Inc., and is provided as a basis for understanding the potential uses of the products mentioned. Due to the numerous variables in methods, materials and conditions of producing art, Golden Artist Colors, Inc. cannot be sure the product will be right for you. Therefore, we urge product users to test each application to ensure all individual project requirements are met. While we believe the above information is accurate, WE MAKE NO EXPRESS OR IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, and we shall in no event be liable for any damages (indirect, consequential, or otherwise) that may occur as a result of a product application.